Brief Information about paper used for Offset Printing

When you have ideas for a publication, choosing the right kind of paper is not an easy and simple task; Otherwise, besides production costs (depend on expensive or cheap paper), it must ensure the aesthetics and efficiency of use ... For everyone to have an overview of commonly used paper in printing industry today, kythuatin.com would like to introduce an article about this topic

Paper and Its Basic Characteristics

Printing paper is one of the main materials used in the printing industry. Basically, paper is made from wood pulp such as bamboo, cotton, jute ... and even recycled paper (also known as recycled or secondary). This is the source of cellulose fiber in the plant, or all the ingredients contain cellulose. In addition to cellulose in paper, there are additives to increase whiteness, smoothness, reflectivity, etc. Additives are commonly used for printing papers are called fillers. Filler-type paper is also called coated paper.

Fillers are white, smooth, water insoluble substances added to the pulp suspensions to increase some of the important properties of paper such as whiteness, turbidity, fineness, smoothness, reduce deformation of paper when contacting with water and reduce the cost of paper. Commonly used fillers are CaCO3 limestone powder, Al2SO3 kaolin, talc powder MgO.SiO3.nH2O, TiO2...

The fillers in the pulp suspensions will fill the gaps between the fibers. Most types of paper use fillers. The disadvantage of the filler is that it reduces the bond between fibers by reducing the resistance, hardness... The content of fillers used can be up to 20-35%.

Paper production in the printing industry is usually in rolls (most rolls are cut to standard size sheets for printing). In addition to paper size, the paper has some technical characteristics as follows:

1. Thickness of paper: This is one of the important parameters of paper. Under certain conditions, along with the increase in thickness is the change in durability, compressive strength and penetration, reflectance... of the paper. Typically, paper thicknesses range from 0.03 to 0.25 mm, except carton paper can have a thickness of more than 3mm.

2. Basis Weight: is the weight of a square meter of paper (gsm). Standard paper weighs from 38gsm to 500gsm, and carton paper can reach to 2000gsm. Paper weight is usually proportional to the thickness and hardness of the paper.

3. Ash Content: The weight of the material left after calcination under the standard conditions of the test method. In other words, the amount of ash obtained after burning the paper. The ash content is the amount of inorganic minerals (additives) contained in the composition of the paper. Unit weight is % of ash; ordinary paper has an average ash content of 18-23%.

4. ISO Brightness: The light reflectance factor of an ideal reflective sheet of paper pulp, sheet paper at a wavelength of 457nm is determined on a standard measuring instrument specified in the test method. Whiteness is characterized by a percentage compared to the standard whiteness of Brioxide (chemical formula is BaO). Photographs that have good image quality should have a whiteness of 70% or higher.

5. Air Permeability: The characteristic of the paper indicates the ability to allow air to pass through its fiber structure, as determined by the standard test method. The higher the deformation, the greater the deformability of the sheet.

6. Dimensional Stability): The ability to retain the shape and size of the paper when moisture changes, or under other effects such as changes in the surrounding environment, physical stresses, mechanics during printing and machining operations or when used. The higher the paper's stability, the lower the paper's ability to stretch.

7. Smoothness: Characteristic properties to evaluate the flatness of the paper surface. This characteristic is determined in the standard test methods. The higher the transparency, the better the quality after printing.

8. Moisture Content: is the amount of water contained in the material. In fact, it is the ratio of the weight loss of the sample, when drying under the standard conditions of the test method and the weight of the sample at the time of sampling, expressed as %. This is a characteristic to keep in mind when printing on printers that use a thermal system to print inks such as UV, vecni.

9. Bursting Strenght): The force act perpendicularly to the largest surface of the sample, before bursting under the specified conditions of the standard test method. For thick paper used for making box, it is necessary to have a large index to ensure the quality in the process of printing, post ... after printing.

10. Tensile Strenght: The maximum pull force that the sample will withstand before breaking under the specified conditions of the standard test method.

11. Breaking lenght: The calculated length of a paper with uniform width has a weight that is heavy enough to break itself when it is hung up.

12. Stretch at break: The elongation is measured at the break-point of the carton paper tape when it is stretched under the specified conditions of the standard test method; the unit of expression is usually % compared to the initial length of the sample.

When producing paper bags, depending on the purpose of use, we choose the suitable type of paper with the tensile strength, the length and elasticity.

13. Absorbency: Absorbability and retention when exposed to water of paper; or water absorption rate, is determined by standard test methods.

14. Opacity: The ratio is expressed in % of the amount of reflected light from a sheet of paper placed on a black object and the amount of reflected light of the paper itself lies on the white object in the condition of standard test method.

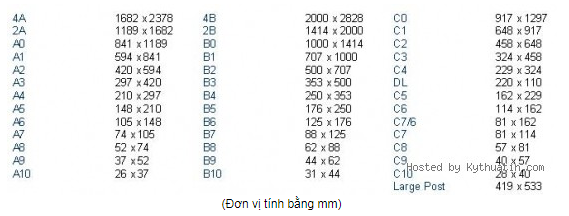

Common paper size used in the printing industry (paper size)

There are many standards of paper rates used in different countries and at different periods in history. However, today the world's two most widely used and almost popularly used standards are the common standard for all countries, which are the standard system of the International Organization for Standardization (ISO) A4, A3, B3, C3....), and the standard system used in North America (standard for lettter, legel, ledger, ...). These two systems has positively effected the production and use of stationery especially printers, photo and printing equipment.

International Organization for Standardization (ISO)

The paper size in accordance with international standard EN ISO 216 comes from DIN 476 standard, issued by the German Institute (Deutschen Institut für Normung - DIN) in 1922. The paper size specifications in this standard are as follows:

- The size is always written with the shorter side first.

- All dimensions in A, B and C row are rectangles with the ratio of 2 sides is a square root of 2, approximately 1.414.

- The area of A0 paper is specified as 1m². The sides of the A0 scale are thus defined as 841x1189mm

- The sizes in the same row are in the reversed order, the latter is equal to 50% of the previous size (divided by cutting the previous size along the line parallel to the short edge)

+ The sizes of row B are inferred by taking the average multiplication of the successive sizes of row A.

+ The sizes of row B are inferred by taking the average multiplication of respective sizes of row A and B.

+ The size of row A, B and C are calculated as the following table:

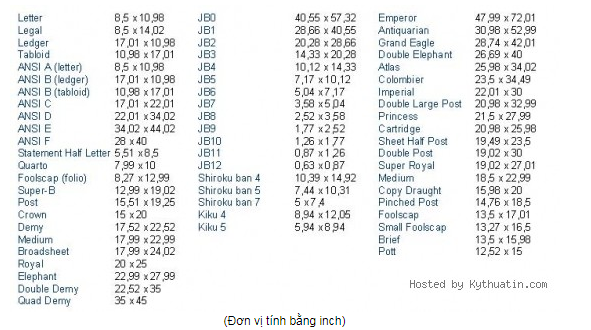

North American Standard

- Standard US paper sizes are based on the following: "Letter", "Legal", and "Ledger" / "Tabloid" are extended sizes for everyday work. Letter size is based on unit of measure “Inch” (8.5 "x 11" = 215.9mm x 279.4mm)

Common types of paper used in the printing industry

There are many types of paper available in the market today. According to unofficial statistics, more than 100 different types of paper are used. In Offset printing, the paper is divided into two main types, coated papers and uncoated papers.

Coated papers are glossy and highly reflective papers (due to the coating which increases the brightness), so that the reproduction of the colors can be faithful for pretty printing. The most commonly used coating is kaolin, stone powder and also paper coated with metal (metaline paper). There are two types: one-side coated paper and two-side coated paper. The papers are commonly used in this group are:

+ Couches, matt couches (these are usually smoother than normal Couche type, the facestock has a faint feel): These are two popular papers used in high-end books, newspapers, magazines, catalouge, brouchure and other advertising publications.

+ Briston, Ivory (higher hardness than couche types): Used for high-end printing such as cosmetic boxes, medicine boxes, paper bags, wall calendars...

+ Duplex (usually weighing 250gsm or more): This is the type of thick paper used in large-scale box printing.

+ Decal Paper: there is one side coated with glue adding a release liner

In the coated paper type, there is also a crystal paper coating with gielatin glue, so it is glossy like mirror.

Uncoated Papers are paper that has a rough surface, not glossy. However, depending on the whiteness of the paper, the uncoated paper also gives different colors of the image. Typically, when printing on this type of paper, the sharpness of the image is only average. The basic difference of this type of paper compared to coated paper is that it can be written on the paper by the normal pens. The papers are commonly used in this group are:

+ White Fo paper: Paper imported or produced in Vietnam by companies like Bai Bang, Tan Mai... This type of paper has a high whiteness (68% or more). This is the type of paper that is used in envelopes, letterhead, photocopy in the office, printing 1 to 2 color books...

+ Yellow Fort paper: Paper has a low whiteness (less than 60%) and usually falls yellow. This paper is commonly used in printing textbooks of Vietnam Education Publishing House. The advantage of this type of paper is the low cost due to domestic production of paper companies such as Bai Bang, Tan Mai, Dong Nai ...

+ Kraft paper is paper made from chemical pulp of softwood processed by kraft processes. Kraft is tough, flexible and rough. The grammage is normally 50-135 g / cm2. Kraft paper is usually brown but can be bleached to produce white paper. Kraft paper is usually made of grocery bags, multiwall bags, letter envelopes and other packaging.

+ Carbonless paper: This is the paper used to print invoices, coupons. On the surface of the paper is coated with a drug, under the pressure of this drug will break off and form the paper on the paper.

+ Art paper: when looking at the tendon tissue paper, this type of paper usually has many colors and many types are used in printing invitation cards, calendars, cardvisit... Especially this paper when printing ink color (inject) gives very good color quality.

Source: kythuatin.com